The asparagus visual sorting line is a system that uses computer vision technology to automatically sort asparagus. It captures images of asparagus through cameras, then uses image recognition algorithms to identify and classify the quality, size, shape and other characteristics of asparagus, and finally distributes asparagus of different qualities to different outlets. Depending on the output, it can be designed as a single-channel or multi-channel device.

The processing flow of asparagus: cutting – sorting – packaging.

Asparagus visual sorting line equipment mainly consists of the following parts:

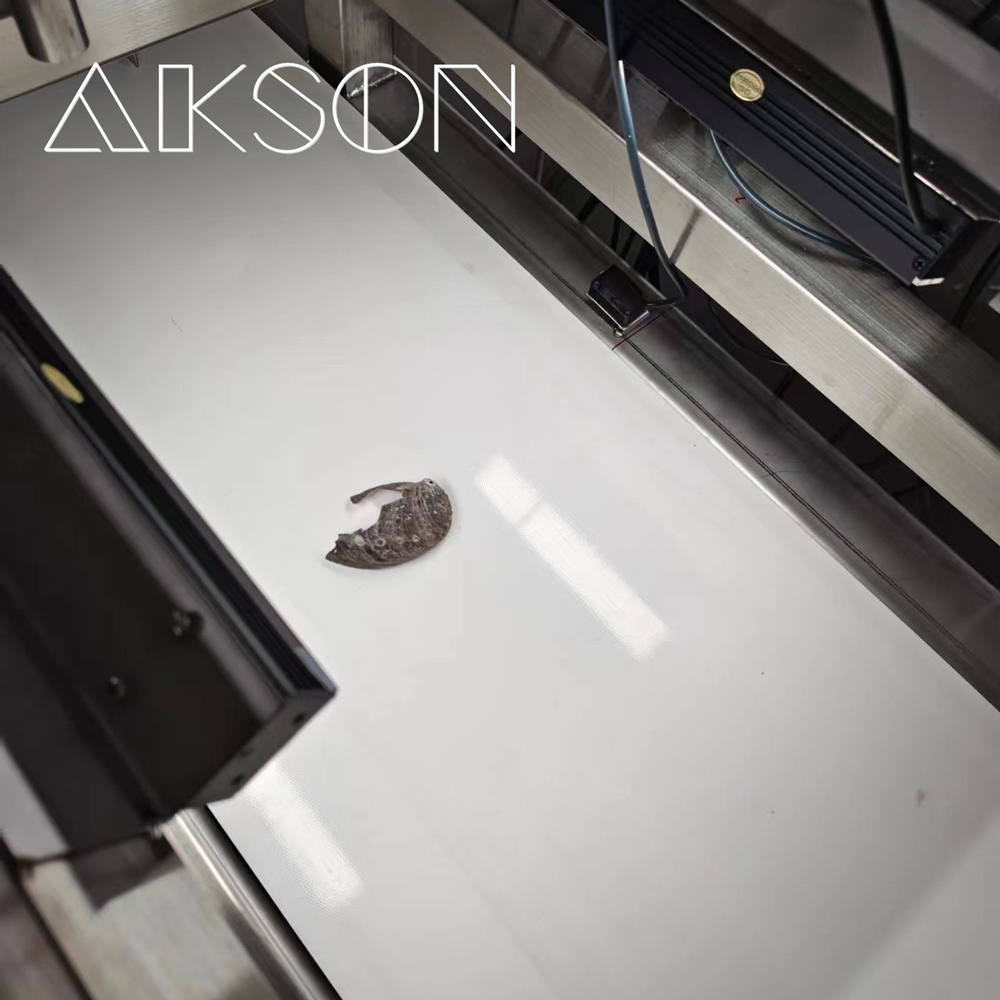

Conveyor system: used to convey asparagus to the sorting area. Equipment such as conveyor belts or vibrating plates are usually used to transport asparagus efficiently and evenly.

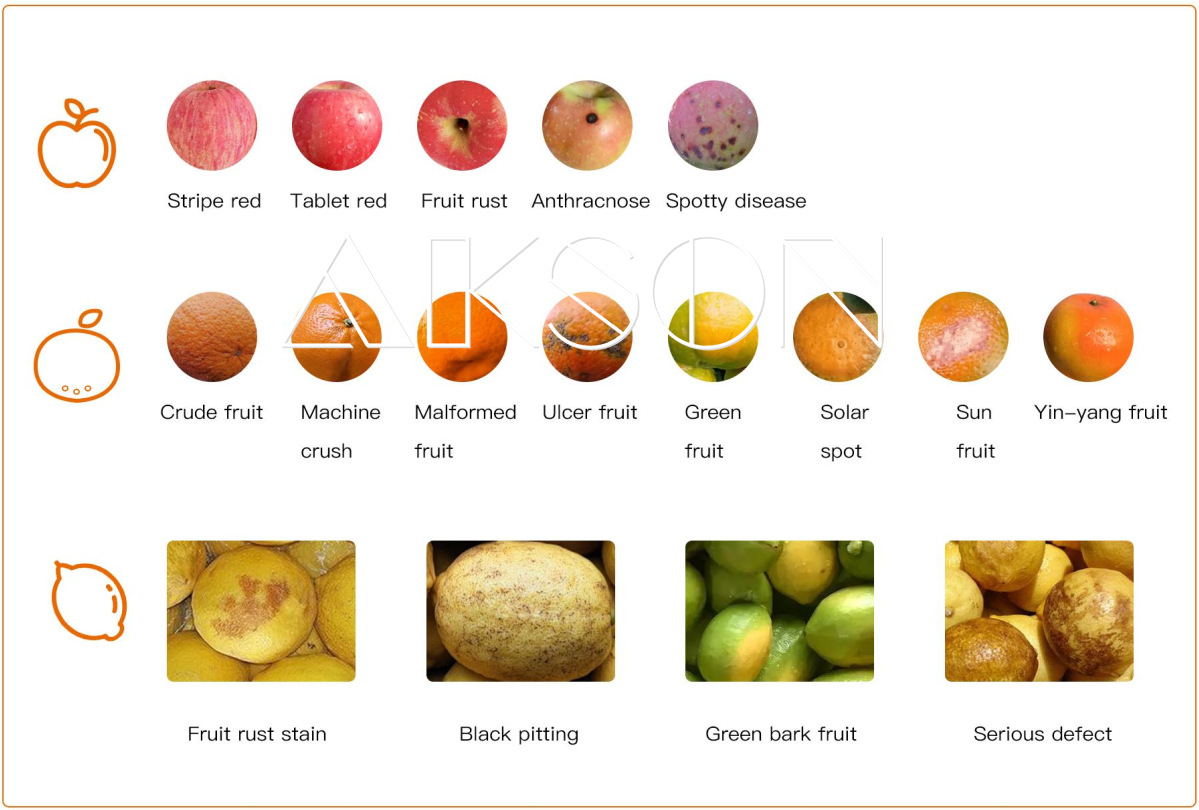

Vision system: used to collect image information of asparagus. Equipment such as high-resolution cameras and high-brightness light sources are generally used to ensure accurate acquisition of the shape, size, color and other characteristics of asparagus.

Image processing system: Process and analyze the collected image information. Algorithms are used to identify and classify the characteristics of asparagus, thereby determining the quality and grade of each asparagus.

Sorting Execution System: Sorts asparagus into different categories based on the results of the image processing system. Equipment such as robotic arms and pneumatic valves are usually used to quickly and accurately classify asparagus.

The workflow of this equipment is: asparagus enters the sorting area through the conveying system, the vision system collects image information, the image processing system analyzes and processes the image, and then based on the processing results, the sorting execution system sorts the asparagus into different categories .

weight sorting machine, grading mahcine

weight sorting machine, grading mahcine