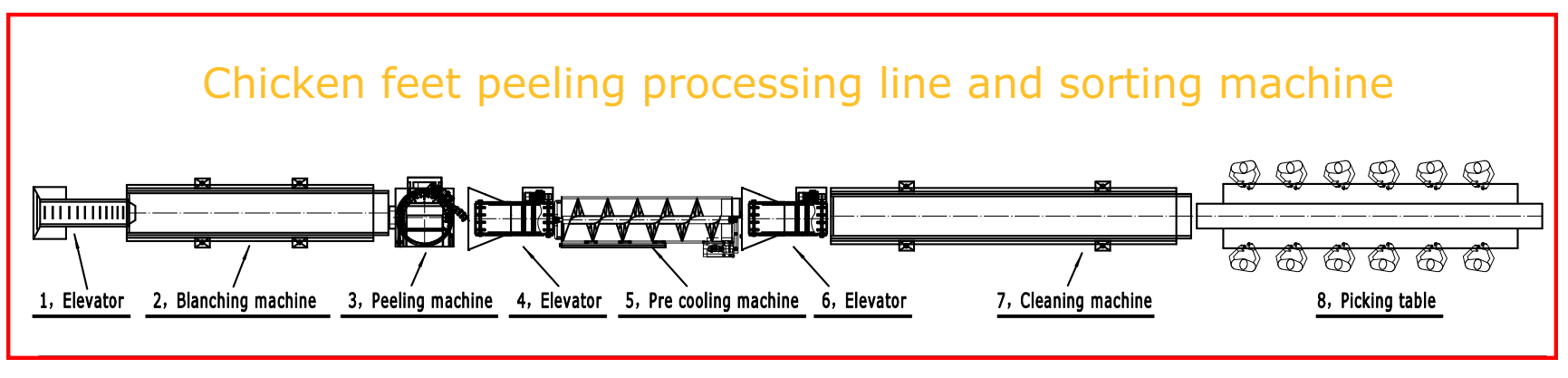

Chicken feet peeling processing line /Chicken feet blanching machine/peelilng line and sorting machine

The processing is:Elevator- Blanching machine(Include steam boiler)- Peeling machine- Elevator- Pre cooling machine- Elevator- Cleaning machine- Picking table

The Chicken feet peeling processing line is a series of machines and equipment used in the food processing industry to produce peeled chicken feet. The processing steps involve:

Elevator: This machine is used to transport chicken feet from one processing station to another.

Blanching machine: This machine is used to pre-cook the chicken feet to make it easier to remove the skin and improve the texture. It includes a steam boiler to heat water or steam.

The surface of chicken feet is attached with a layer of yellow skin, which needs to be removed when entering the market. The normal process is to blanch, peel, pre-cool and clean.

Chicken feet blanching machine,

Blanching machine for chicken feet is mainly used for blanching the skin of chicken feet. The equipment adopts stainless steel mesh belt setting, frequency conversion control conveying speed, so that the chicken feet can be blanched evenly.

The equipment is equipped with pneumatic Angle seat valve blanching pool temperature will automatically fill steam or heat energy. When the setting temperature is reached in the blanching tank, the heat energy is automatically turned off to save energy. The blanching machine is suitable for the pre-cooking process of chicken feet, with good temperature control, high efficiency, labor saving and so on.

The equipment is equipped with air pump and circulating pump to let the water flow in the blanching pool, and the water temperature in the pool is uniform. The blanching tank body is designed with insulation layer to reduce the loss of heat and save energy.

The upper end of the equipment is provided with an overall lifting device to facilitate internal cleaning, and the lower end is provided with a square sewage outlet to facilitate the cleaning of the machine.

Peeling machine: This machine is used to remove the skin and feathers from the chicken feet.

Elevator: Again, this machine is used to transport the peeled chicken feet to the next processing station.

Pre cooling machine: This machine is used to reduce the temperature of the chicken feet quickly to prevent spoilage and improve its storage life.

Elevator: Again, this machine is used to transport the cooled chicken feet to the next processing station.

Cleaning machine: This machine is used to remove any remaining feathers, dirt or other impurities from the chicken feet.

Picking table: This is a manual process where a worker checks the chicken feet for any remaining impurities and separates them into different grades based on quality.

The chicken feet peeling processing line is designed to produce peeled chicken feet efficiently and hygienically, while ensuring the quality and safety of the final product.

Chicken feet weight sorting machine is a machine used in the food processing industry to sort chicken feet based on their weight. The machine typically works by placing the chicken feet on a conveyor belt and passing them over a series of weight sensors. The sensors accurately measure the weight of each chicken foot and categorize them into different weight groups based on pre-defined weight ranges.

The chicken feet weight sorting machine is designed to improve the efficiency and consistency of the chicken feet production process by removing any manual labor involved in weight sorting. Additionally, the machine can also help to ensure that the final product meets specific weight requirements, which is important for many food processing operations.

This type of machine is commonly used in poultry processing plants, where the weight of the chicken feet is a critical factor in determining their value and marketability. The use of a chicken feet weight sorting machine can help to reduce the time and costs associated with manual weight sorting and improve the overall quality and consistency of the final product.

weight sorting machine, grading mahcine

weight sorting machine, grading mahcine