Crispy pork sorting machine are specialized equipment designed to categorize and sort crispy pork products based on various criteria such as size, weight, shape, and quality. These machines are used in food processing facilities to ensure uniformity and quality in the final product. Here are some common types of crispy pork sorting machines and how they work:

Types of Crispy Pork Sorting Machines:

1, Size Sorter

Grading by Size: These machines use screens or conveyors with adjustable gaps to sort crispy pork pieces based on their size. Smaller pieces fall through the gaps while larger ones are carried forward.

Sieve Sorters: Utilize vibrating sieves with different-sized openings to separate pork pieces into various size categories.

2, Weight Sorter

Multihead Weighers: These machines have multiple weighing heads that measure the weight of each piece. The pieces are then directed to different output lanes based on their weight.

Checkweighers: Positioned on conveyor belts, these weigh individual pieces as they pass through, sorting them into categories based on pre-set weight ranges.

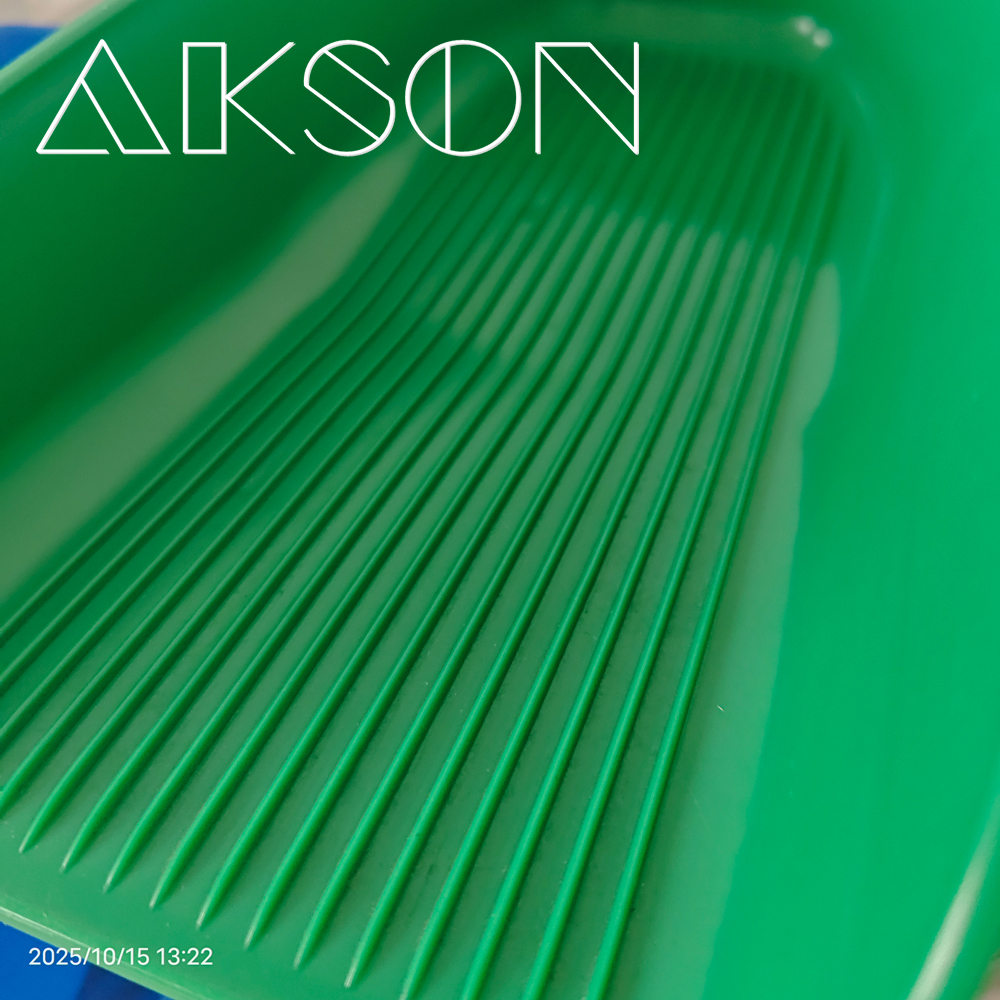

3, Shape and Visual Sorter

Optical Sorters: Use cameras and image processing software to analyze the shape and appearance of crispy pork pieces. They can identify and sort pieces based on size, shape, color, and even detect defects.

Laser Sorters: Utilize laser technology to measure and sort based on the shape and surface characteristics of each piece.

Quality Sorters

1, X-ray Sorters: Employ X-ray imaging to inspect the internal structure of crispy pork pieces, ensuring they meet quality standards by detecting foreign materials or inconsistencies.

2, Infrared Sorters: Use infrared sensors to detect the moisture content and texture of the pork, ensuring only properly cooked and crispy pieces are sorted.

Manual Sorting Lines

Human Inspection: In some cases, human workers are employed to manually sort crispy pork pieces based on visual inspection. This method is less common in large-scale operations but can be used for final quality checks.

How Sorting Machines Work:

A, Feeding Mechanism

A.1, Conveyor Belts: The pork pieces are fed onto conveyor belts that transport them to different parts of the sorting machine.

A.2, Vibratory Feeders: These use vibration to evenly distribute the pork pieces onto sorting surfaces.

B. Detection and Measurement

Sensors and Cameras: These detect and measure attributes such as size, weight, and shape. Advanced systems may use multiple sensors and cameras to get a comprehensive analysis.

C. Weighing Systems: Integrated scales or weigh cells measure the weight of individual pieces.

D. Sorting Mechanism

D.1, Air Jets: High-speed air jets are used to push pieces into different bins or conveyors based on sorting criteria.

D.2, Mechanical Gates: Flaps or gates that open and close to direct pieces into different chutes or bins.

D.3, Robotic Arms: In advanced systems, robotic arms pick and place pieces into designated areas based on sorting data.

E. Output and Collection

Sorted Bins: Different bins or containers are used to collect the sorted pieces.

Conveyor Belts: Sorted pieces may be directed onto different conveyor belts for further processing or packaging.

Advantages of Using Sorting Machines

Efficiency: Automated sorting significantly increases the speed and consistency of sorting operations.

Accuracy: Reduces human error and ensures precise sorting based on predefined criteria.

Quality Control: Helps maintain high quality by detecting and removing defective pieces.

Labor Savings: Reduces the need for manual labor, cutting costs and improving workplace safety.

Using sorting machine in crispy pork processing ensures a high level of product consistency, quality, and efficiency, which is crucial for meeting industry standards and consumer expectations.

weight sorting machine, grading mahcine

weight sorting machine, grading mahcine