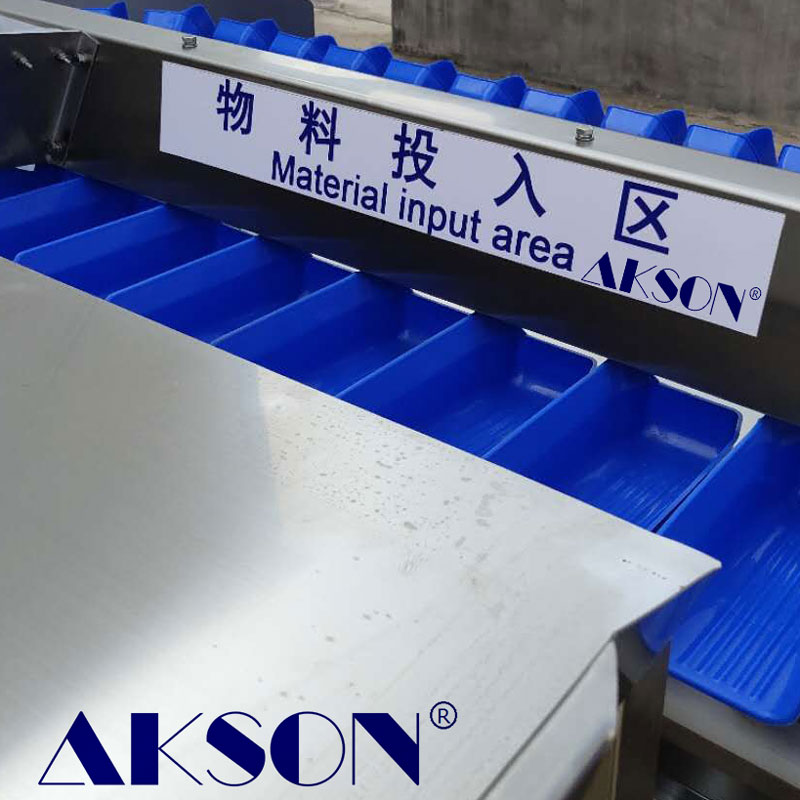

The weight sorting machine characteristic :

The weight sorting machine is a device mainly used for automatic weight detection. Upper and lower limit discrimination or weight classification selection on automated assembly lines and logistics conveying systems. This type of weight sorting machine can be applied to online inspection in the manufacturing, food, toy, five, chemical and other industries. In addition, the weight sorting machine can directly replace manual weighing. Thereby improving production efficiency and weighing consistency and reliability.

Function:

Large-size color LCD touch screen interface, simple operation and intuitive display.

It can store up to 2G of detection data, which is convenient for users to call.

The USB data storage interface can transfer report data to a PC for analysis and printing.

The parameter setting is password protected, and it can only be operated by management personnel.

Automatic zero tracking system, reliable detection data.

Built-in temperature and noise compensation system, system stability.

Online printing function (customer required).

Data external communication interface, which can be connected to other equipment in the production line (such as: labeling machine and inkjet printer) (customization required).

Multiple rejection devices: push rod rejection, fall rejection. (Customer required).

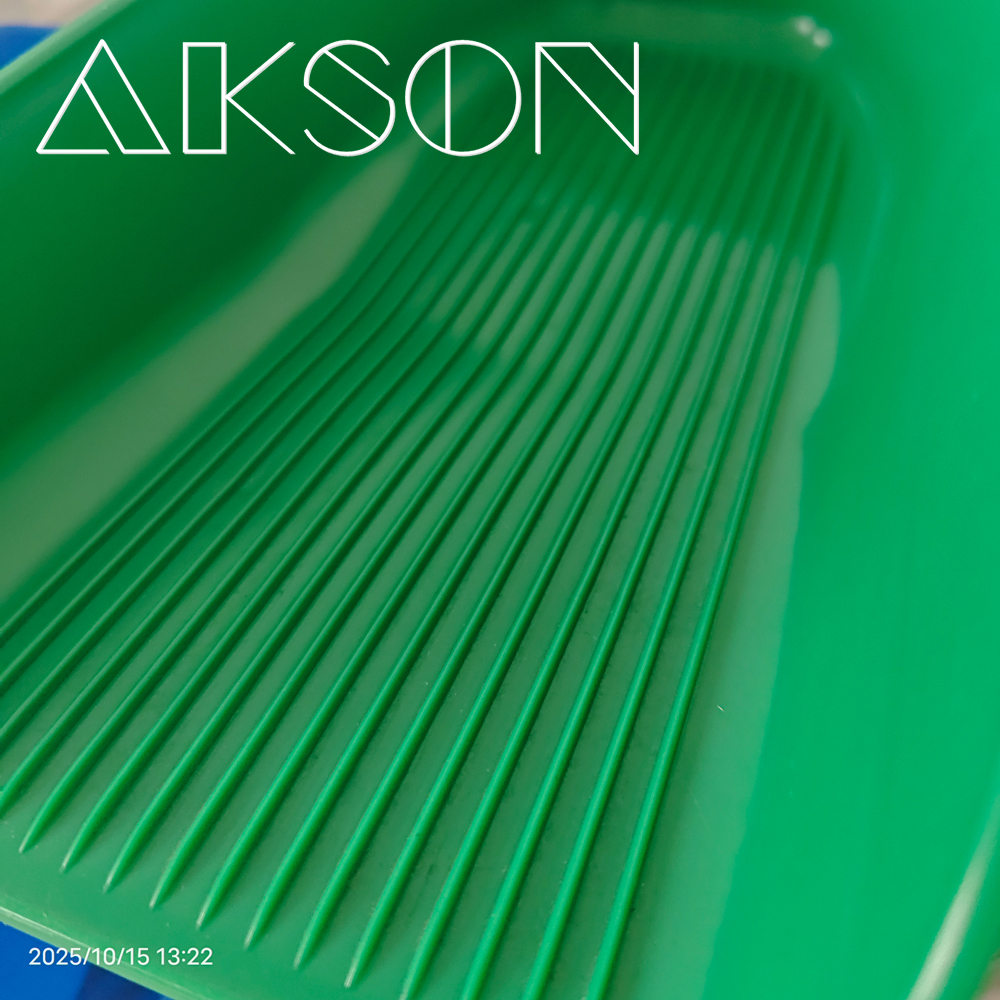

The mechanical structure is simple, easy to disassemble, clean and maintain.

parameter:

Weighing range: within 3KG

Weighing accuracy: ±0.5g

Display resolution: 0.1g

Sorting speed: 320 pcs/min

Motor power: AC 220 volts (fluctuation +10%, -15%, 50/60 Hz)

Working temperature: from 0°C to 40°C

Humidity: 90% relative humidity (no condensation)

Weighing frame material: made of 304 stainless steel

weight sorting machine, grading mahcine

weight sorting machine, grading mahcine