Глубокое обучение. Введение в систему визуального контроля.

1, Professional soreware algorithms industrial research and development team

Universal dual speed customized high resolution industrial camera With light source and full field of vision of light source control system.

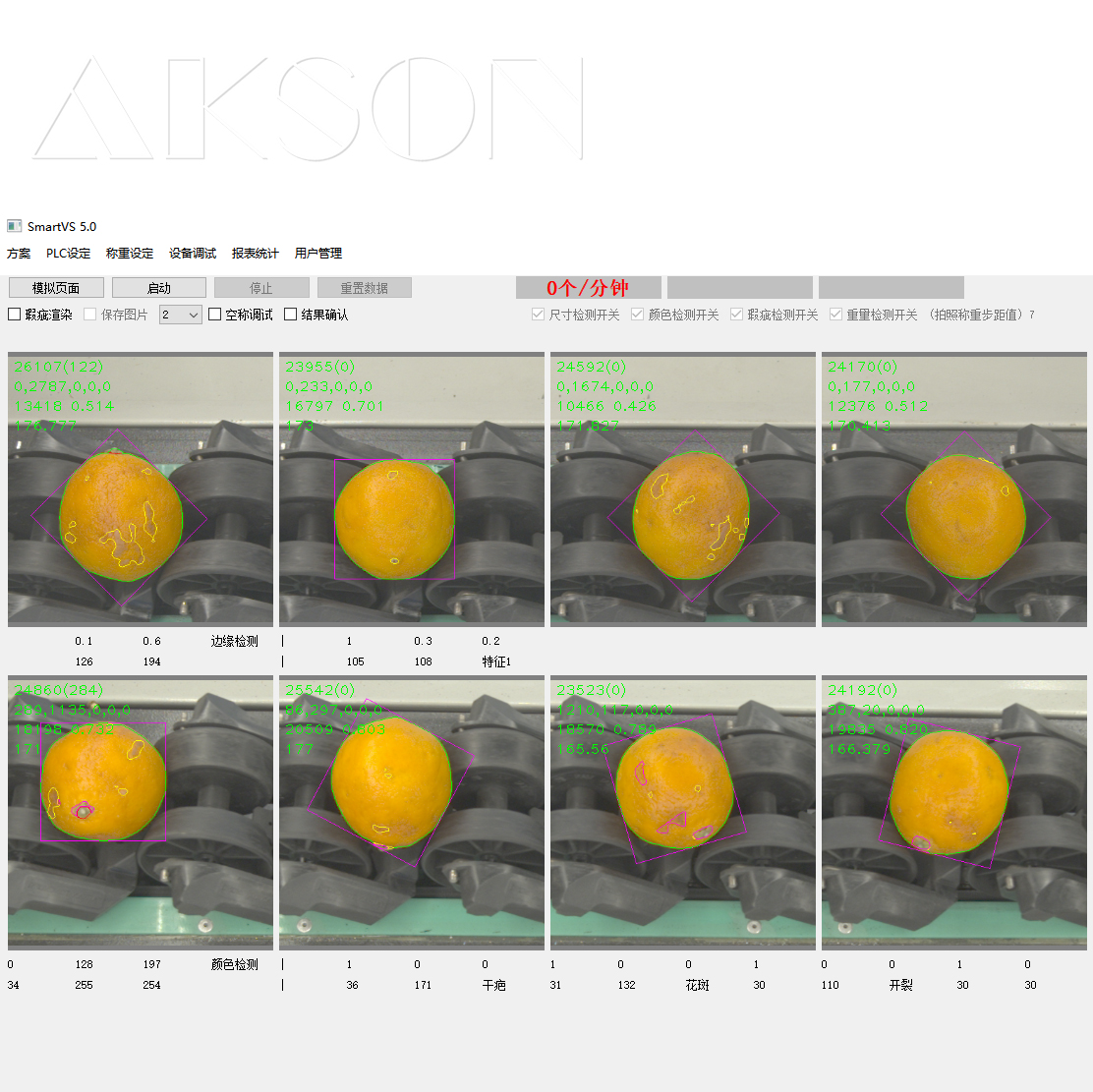

The ROI region of the original image is captured by a high-speed camera. And it is input into the Al visual inference engine. And the detection results are calculated and transmitted to the host computer.

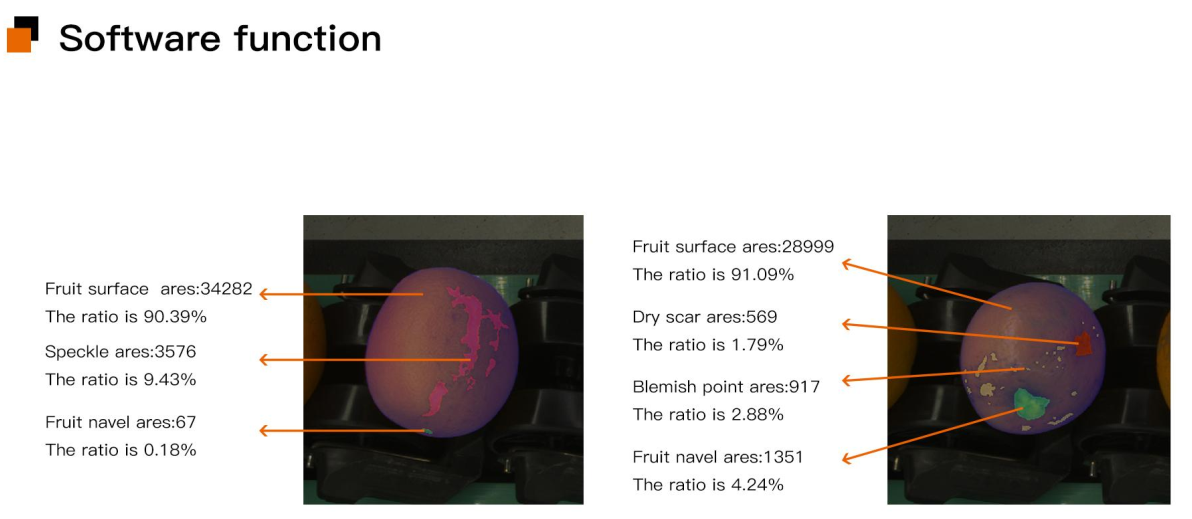

Using traditional vision merges depth vision technology scheme, traditional vision can quickly carry out digital image. Fruits and veaetables as non-standardized products traditional vision is difficult to achieve operator adaptation. We combine the deep vision algorithm with the traditional algorithm. And the two advantages complement each other to achieve. accurate defect feature detection of fruits and vegetables. And easy to use modeling process.

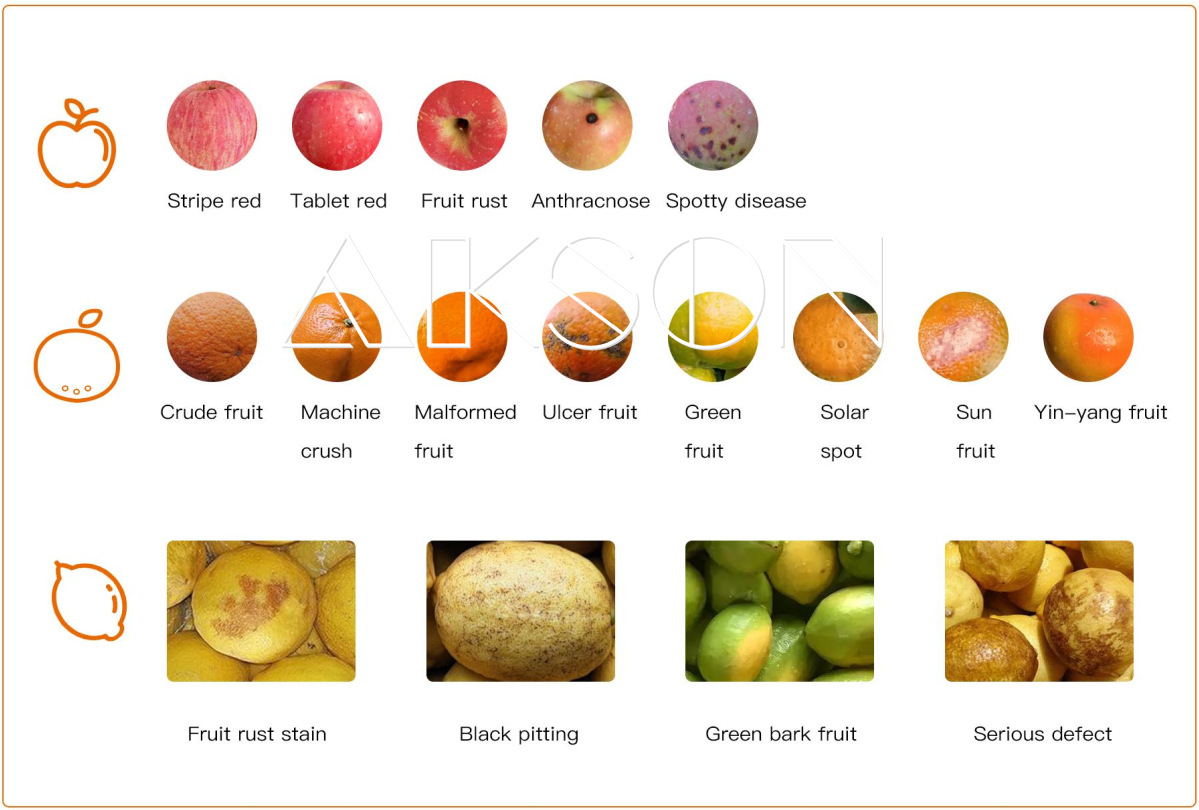

For different fruits, define diggerent defects and standards, customized modeling.

2, Fast and easy to use modeling process

Deep learning requires modeling based on fruit categories collected on site. Software can build different models according to different requirements. Users can define the features, contour and defects of the fruit to carry out personalized design.

3, Comprehensive function, humanized operation. Professional and complete function

Perfect function. Different solutions can be saved for different product categories. User management to achieve different permissions of personnel operations. Preview and print re- ports, It also supports various debugging collection functions. And help customers analyze and locate problems.

Humanized operating system

The main display interface is simple, easy to operate, and can update image data and sta- tistics data in real time. Different programs can be set for different products, convenient to save and call parameters.

весовая сортировочная машина, сортировочная машина

весовая сортировочная машина, сортировочная машина